|

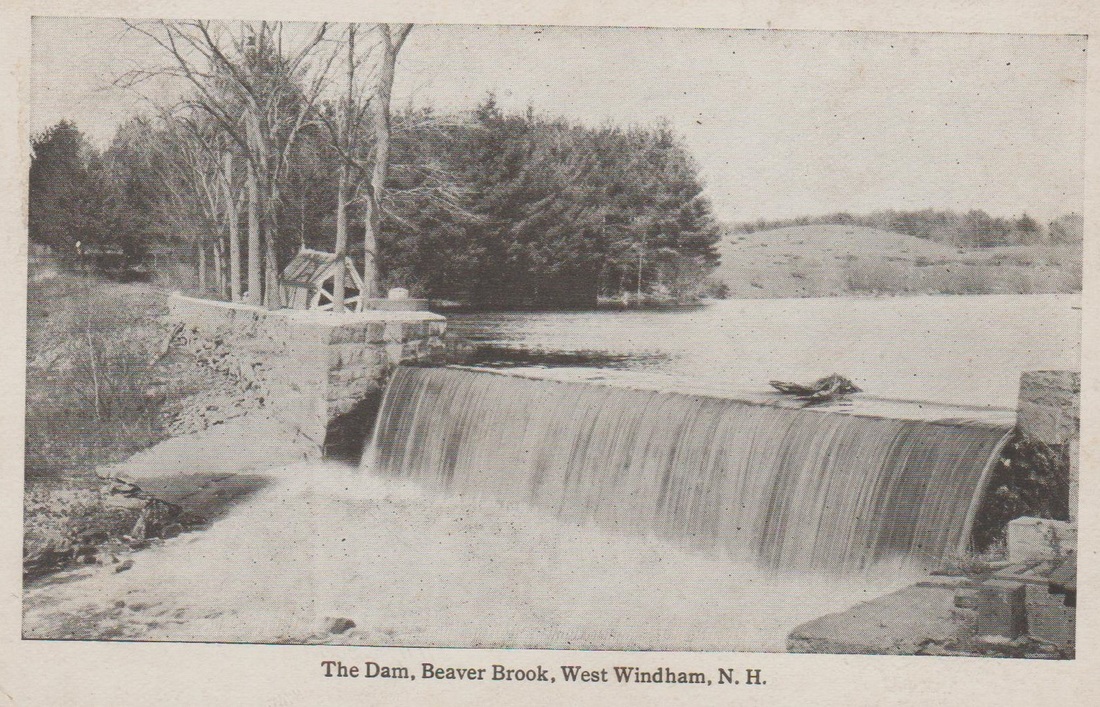

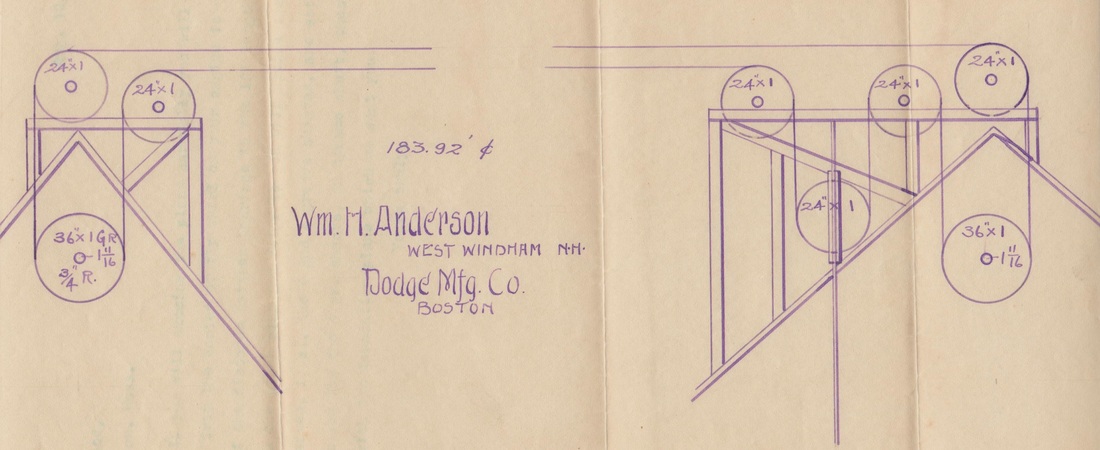

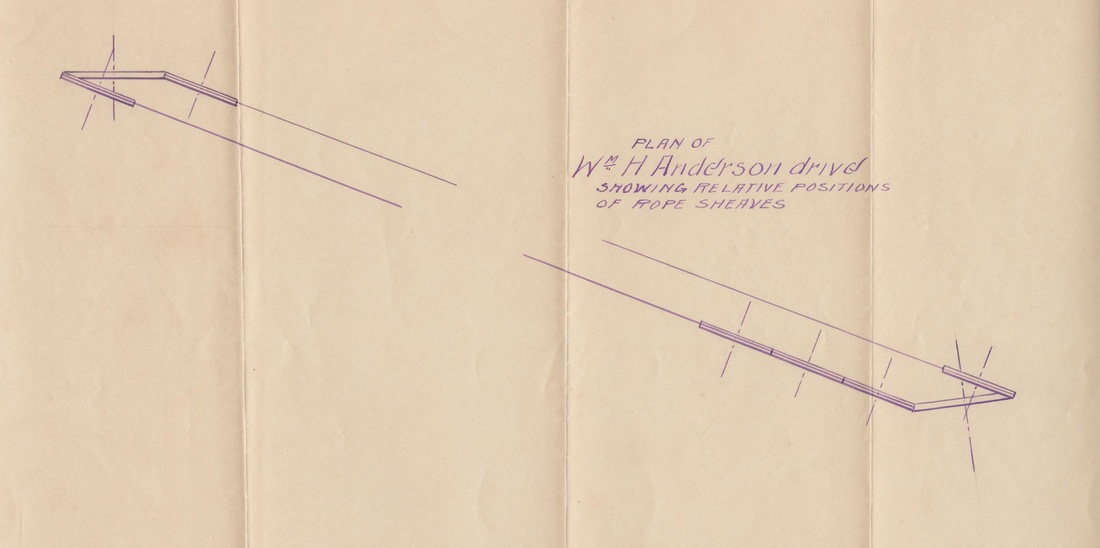

Beaver Brook proved to be a valuable source of power for the many mills that have operated on its shores since colonial times. However, many of the early mills were powered by large water wheels. The flow of the water would turn the wheel, which would then spin belts running machines, such as an industrial size saw. Many other local mills also took advantage of the power of water, including Neal's mill on Golden Brook. However, the dam fell into disrepair and by the late 1890s it completely let go; it was not rebuilt. In the first decades of the 20th century Walter Drucker's mill in West Windham was the last mill in town to still use water power. Drucker used the power to operate machinery to grind the grain that he sold from his small store in West Windham. Instead of using a simple waterwheel setup like the mills of centuries ago, Drucker utilized a more efficient, complex system of a wire belt and pulleys. His mill burned to the ground in 1896, but was rebuilt shortly after. It appeared as if luck was not on Drucker's side, as his mill burned again a few years later. In 1900, William H Anderson built a new mill, which is still standing today, on Beaver Brook. As he intended to harness the power of the brook, he engaged the Dodge Manufacturing Company of Boston to design a system to do so. Below are the blueprints drawn by the engineers at Dodge Manufacturing to propose their design to Anderson, as well as to aid in the construction of the system. As Anderson dedicated much of his time to his law practice, he did not intend to run the mill himself. Instead, he hired a Mr. Andrews of Arizona to operate the gristmill until 1910. Walton C Barker succeeded Andrews and managed the mill until 1921. The mill then ceased to operate for several years and was eventually sold.

0 Comments

Leave a Reply. |

AuthorDerek Saffie is an avid Windham historian who enjoys researching and sharing his collection with all those interested in the history of the New England town. Archives

November 2019

Categories

All

|